|

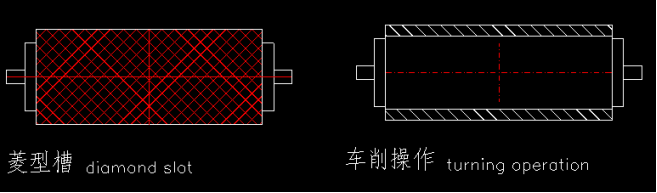

Turning

Roughing the vulcanized rubber rolls, and removing the old glue for the old rubber rollers that need to be re-encapsulated.

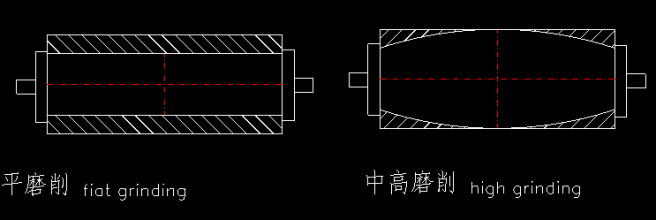

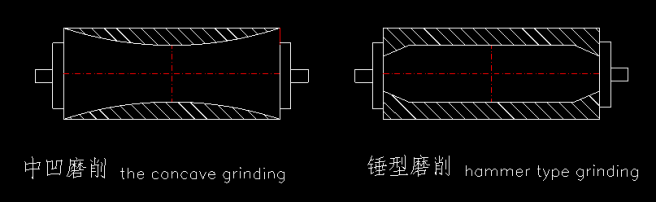

Grinding

The processing of the outer diameter required for the rubber roller. It can be ground in a cylindrical shape, convex in the parabola, concave in the concave, taper, and hammer.

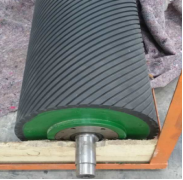

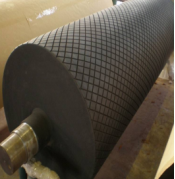

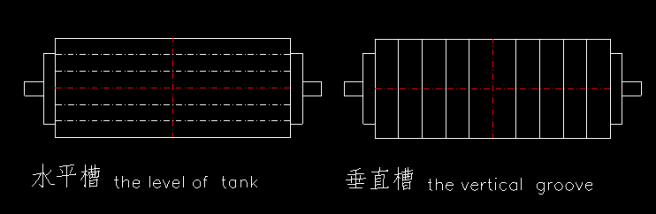

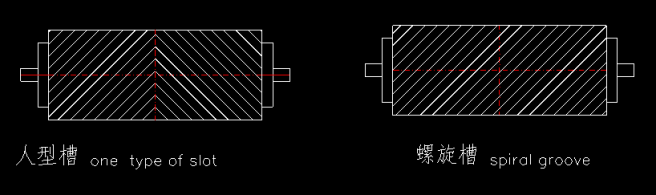

Slotted

Can open spiral, diamond, parallel, vertical, herringbone groove.

Polishing

Requires an iron core grinding machine to achieve the grinding of the rubber core.

Polishing requires a rubber roller polishing machine to improve the smoothness of the rubber roller.

Our machine advantages:

1.We use motion control system, the most advanced CNC system, can be remotely controlled, system upgrade, if the equipment system fails, it can be remotely tested and repaired through the Internet, without the need for engineers to solve the problem on site, saving time and cost very much.

(CNC grinding machine system,First generation, DOS system;Second generation, PLC system;Third generation, servo system;Fourth generation, motion control system,This is the most advanced system at the moment.Robots and robotic arms use this system)

2.Slotting indexing automatic numerical control calculation adjustment, zero error, five-axis CNC,this is very important,if not automatic numerical,if worker calculation error,will waste the whole rubber roller.

Our equipment adopts high-power spindle servo motor, which is directly linked without gap.Higher precision and better product processing quality(Others factory maybe adopt old transmission system The main shaft is two motors, one is slotted, one is grounded, driven by synchronous belt, the operation is troublesome, the manual needs to be switched, and the drag is easy to be lost, and the transverse belt is driven by the synchronous belt drive.)